Ou Zhou Industrial (Kunshan) Co. LTD

Ou Zhou Industrial (Kunshan) Co. LTD

Tel:0512-57451930

E_mail:eouzhou@163.com

Address:Room 624-625, 5 blocks, Henglong International City, 567 Xinnan Middle Road, Kunshan City

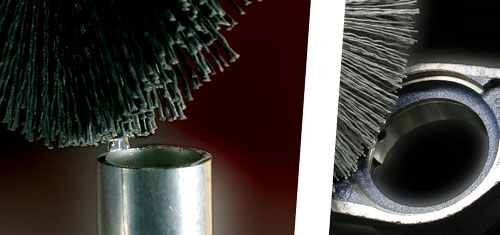

SIT Brushes

The Abrasive Nylon Filament

Characteristics

The filament is composed of a matrix of Nylon 612 with abrasive grains an is ideal as material for the brushes thanks to:

Abrasion capacity

Chemical resistance

Flexibility of the filaments, which allows to process also non plane surfaces

Long lasting

Grits Available

CS - Abrasive Grit in Silicon Carbide:

Circular section filament: from 36 to 500

Rectangular section filament: 80/120/180/320

OA - Abrasive Grit in Aluminium Oxide:

Circular section filament: from 80 to 600

Rectangular section filament: 80/120/180/320

SA - Abrasive Grit in Aluminium Silicate:

Circular section filament grit 2000

Different grits available on demand

SIT has introduced for its range of brushes the new crimped abrasive filament HT150 resistant to high temperatures. HT150 is able to work continuously at the temperature of 150°C and can be recharged with abrasive aggregates of different types and with grit of different size.

Thanks to its resistance to the effects of temperature, the wire can work at sliding linear speed of 60 m/s, superior to those bearable by any other traditional abrasive wire, based on a synthetic matrix of PA 6.12: the brushes using the wire HT150 can therefore generate an abrasion effect 5 times higher than the traditional ones